3D Printing is a technology, also known as Additive Manufacturing, Rapid Prototyping, Freeform Fabrication, Direct Digital Manufacturing, and few other variations as well.

What is 3D Printing Technology?

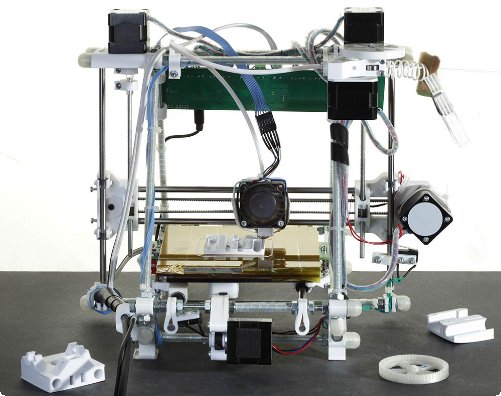

3D printing is an additive manufacturing process that builds a three-dimensional object from a digital file. An object is formed by adding material in layers based on the digital design in a computer controlled process. In other words, 3D printing refers to any computer controlled process that builds an object by adding material in layers following instructions from a digital file.

With a 3D printer, you can transforms your ideas from a 3D CAD design to a real-life functional object! Additive Manufacturing (3D Printing) allows designers to create complex parts and prototypes for machines, airplanes, cars, and other things at the fraction of the cost and time of another production standards.

The technology has been around for approximately 30 years, and with the expired patents in recent years, aggressive developments, and the contribution by the early adopters, the technology is going mainstream today! 3D Printing technology is changing the ways we produce and design objects like tools, toys, clothing, buildings and even body parts, like transplants.The main idea behind it is the ability to make anything you want, anywhere you want it, anytime you want it.

Another thing is that Additive Manufacturing doesn’t necessary mean 3D printing. Processes like metal casting, injection molding, and textile weaving are all additive processes unrelated to 3D printing technology.

Here We’d like to note that when speaking about “Additive Manufacturing” or “Rapid Prototyping” throughout the website, We strictly mean 3D Printing and nothing else.

What is 3D Printing and How does it work animation

How does 3D Printing Work?

Utilizing 3d modeling software, you design the object you want or simply download a model from one of the thousands of free designs available online. After loading the design, an advanced software slices up the object and turns the file into series of commands which guide the printer head. Layer by layer the 3D printer builds up your object by depositing plastics, metals, ceramics or other materials until your object is complete and ready to use! More Info Here.

What can I Make?

Almost anything can think of. You may easily download free designs ready to print or use a variety of 3D modeling software to create almost anything you could imagine. Use it for art, engineering, architecture, recreation, fun or fashion. The applications are limitless. Create tools, toys, games, gifts, figures, models or as a new way to reproduce memories! It’s all designed, customized, personalized and created by you! The questions is not what can you make, but what are you going to make!

The Future of 3D Printing.

Imagine being able to create anything from coffee mugs to human organs with a single technology. 3D printing has the potential to improve people’s lives in every aspect. From everyday basics (kid toys, accessories, crafts, household and office supplies) to items as complex as the next generation implants and prosthetics, 3D printing motivates and inspires creation and innovation.

This progressive technology will bring medical, industrial and consumer revolution. As use increases, cost will lower and it will become more commonplace. We are just beginning to explore more advanced possibilities for life-saving applications, custom created food, printing tools and generating parts in space. In addition it will be simple to create detailed replicas of rare and valuable art, fossils or 3D print a house as well as the ability to scan/clone existing objects and improve them on the spot. See more on the future this exciting industry.

Last updated: 4/28/2017

Leave a Reply

Want to join the discussion?Feel free to contribute!