At the current state of 3D printing technology, certain products can be made efficiently by combining 3D printing with traditional manufacturing methods. The ability of 3D Printers to make almost anything depends on how they operate and partly on the materials they can print with. Let’s take a look at the main advantages and what makes 3D printing so unique!

Complexity is Free

- 3D printing utilizes levels of complexity that simply could not be produced physically with conventional manufacturing. We can print a part with complex structures and patterns that are also lighter and stronger, optimizing the part strictly for it’s purpose.

- Creating shapes only found in nature. Thanks to 3D printing technology, artist and engineers are developing amazing pieces with these structures. Another huge benefit is the lattice and honeycomb like structures, found only in nature can be fabricated, which was nearly impossible before!

- Interlocking parts working straight from the printer. Because 3D Printing is a layering process, material can be applied anywhere on a structure. If the fitting tolerances are correct so the assembly is happening during the printing process.

- Complexity is Free- this is the most important concept when talking about 3D printing. With conventional methods the more complex the part the more it costs and more time it takes to produce. But with 3D printing, the cost is determined from the material used. So with a design specifically tailored for 3D printing the technology creates a successful part for lower cost and in less time.

3D Printed Interlocking Parts

Variety is Free. High Level of Customization and Personalization

- Have you ever wondered why we purchase our clothing in standardized sizes? With traditional production methods, it’s simply cheaper to make and sell thousands of products at an affordable price to the consumer. Alternatively, 3D printing allows for easy customization; one only needs to alter the design digitally to make changes that don’t entail additional tooling or other expensive manufacturing processes. The result? Each and every item can be customized to meet a user’s specific needs without additional manufacturing costs.

Variety Is Free

Speed and Ease to Prototyping

- With today’s services and the low cost entry point to 3D printing, when a 3D design is ready we can prototype or even produce it within a few hours.

- Engineers can create a prototype with a 3D Printer immediately after finishing the part’s Stereo Lithography (STL) file. As soon as the part has been printed, they can begin testing its properties instead of waiting weeks or months for a conventionally made prototype or part to come in.

- Say we have an idea, but don’t have the 3D skills, 3D printer or knowledge of the proper software, finding and hiring a 3D designer is an increasingly simple task.

- For example 3DHubs.com is an online platform providing over 1 Billion people access to 3D Printing. Anyone can “upload” a 3D File, choose color and proper material and then select a LOCAL HUB. These local hubs will print the object, allowing people around the world an opportunity for 3D printed parts. Additionally, anyone owning a 3D Printer can open their own hub and, while earning money, can help others develop their ideas.

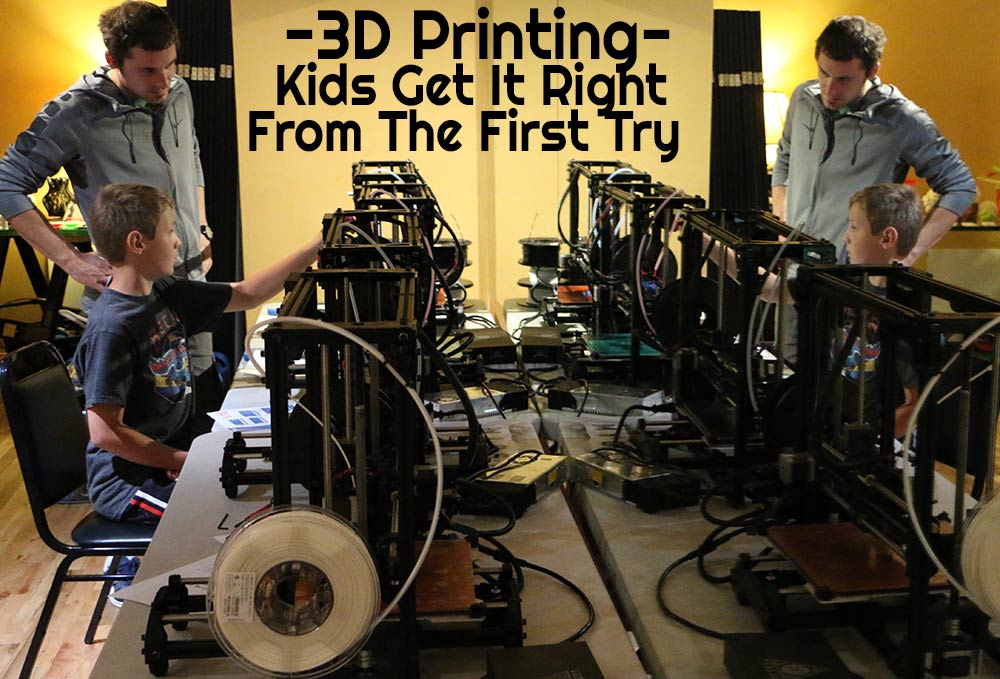

Little Manufacturing Skills

- While complicated parts with specific parameters and high-tech applications are typically professionally made, some children in elementary schools have begun to create their own figures using 3D printing processes. This technology is the most direct way to manufacturing and with only few lessons anyone can have the basics skill to 3D print!

Little Manufacturing Skills. Even Kids Can Do It

Fewer Constraints

- Let’s use the cliche- your imagination is the limit. Anything you can dream up and design in the CAD software, you can create with Additive Manufacturing as long as the design meets the machine specifications with the chosen material requirements.

No Need for Tools and Molds. Lower Fixed Cost

- With metal casting or injection molding, every part of each product requires a new mold – a factor that can balloon manufacturing costs very quickly. To recoup these upfront manufacturing costs, most companies rely on thousands of the same item being sold. Alternatively, because 3D printing is a “single tool” process, there is no need to change any aspect of the process preventing additional costs and lead times between making an object. Ultimately, this leads to substantially lower fixed costs.

Faster and less risky route to market

- Because here is no expensive tooling required to create objects through 3D printing, it is a particularly cost effective method for designers and entrepreneurs who are looking to do market testing or small production runs. They can even launch their products through crowdfunding sites like Kickstarter. It is very easy for design changes to be made without compromising more formal – and expensive – manufacturing orders. Thus, 3D printing offers a much less risky route to market for those who are looking into manufacturing a product idea.

Green Manufacturing

- Improved environmental and sustainable processes

- Many conventional manufacturing processes are subtractive: you start with a block of material, cut it, machine it, and mill it until it has been processed into your intended design. For many products – such as a bracket for an airplane – it’s normal to lose 90% of the raw material during this process.

- 3D printing is an additive process; you create an object from the raw material layer by layer. Naturally, when an object is manufactured this way, it only uses as much material that is needed to create that particular object. Additionally, some of the materials used can be recycled and repurposed into more 3D printed objects.

- Smaller carbon footprint

Manufacturing on Demand

- With traditional manufacturing, it is much faster and cheaper to manufacture excess products that are eventually needed. However with 3D printing, only products that are sold need to be manufactured, reducing surplus inventory.

Economic Low Volume Production

- With 3D printing, many of the intermediary steps in manufacturing become unnecessary or redundant. Eventually, manufacturing an item could be as simple as entering the program on your home 3D Printer, inserting the raw materials, and assembling your parts when they are printed. This is a huge benefit for those working in remote areas of the world

Economic Low Volume Production. Risk Free.

More Office Jobs

- More engineers are needed to design and build 3D Printers, and more technicians are needed to maintain, use, and fix the printers as well. And with the lower cost of manufacturing, more designers and artists will be able to deliver their products to the market. Domestic jobs, like those for shipping products, would be created too.

New Combination of Materials

- Mixing types of materials is not always possible with conventional methods due to high costs involved. But 3D Printing has eliminated some of those boundaries. Raw materials can be mixed and parts with new mechanical properties are being made on the fly. Progress has been made experimenting with a mix of different materials and types of metal powders and fusing them together with laser.

New Business Models

- With all this said I will leave this part to you! Maybe you will come up with a new model, a new way of doing business that is better than anything we’ve seen so far! 🙂

Last updated: 4/28/2017

Leave a Reply

Want to join the discussion?Feel free to contribute!